Predictive Modelling of Wastewater Parameters

Sunday, October 19, 2014

Most industries feel uneasy waiting for lab results to come back from wastewater compliance or surcharge testing. They are forced to manage these issues reactively because test results aren’t available until days or even weeks after samples have been collected. Was the process running efficiently? Was the pretreatment equipment working properly? By correlating wastewater data with process data, it is possible to monitor compliance and surcharge results more proactively. Early detection of process upsets or noncompliance episodes can even be achieved through modelling and real-time monitoring of predictor parameters.

The first step is to characterize process wastewaters upstream and downstream of any pretreatment and under various process conditions. All critical compliance and surcharge parameters should be analyzed, together with predictor parameters such as total suspended solids (TSS), turbidity, pH, and chemical oxygen demand (COD). Next, significant sources of all parameters should be identified in production processes, with additional sampling and analysis conducted for each distinct type of process wastewater. Products and raw materials should also be analyzed if possible. Simultaneous data sets should be compiled along different steps in the process and at different times to account for production variability. Relationships within data sets can beevaluated through regression analysis to see which predictor parameters correlate with critical compliance or surcharge parameters. This statistical analysis will help to determine if real-time monitoring of a predictor parametercanbe successful for a specific process or industry. All predictor parameters can easily be monitored in-house through simple instrumentation (hand-held meters or in-line sensors). The monitoring system can be equipped with alarm functionality to notify facility personnel of potential problems before discharging noncompliant wastewater. This provides the ability to manage wastewater issues proactively instead of reactively.

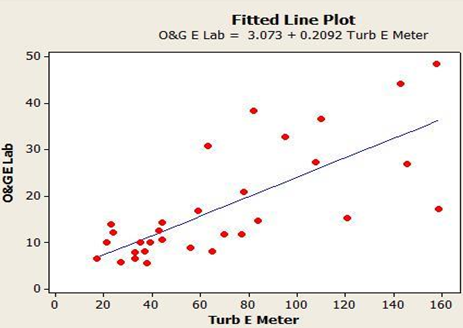

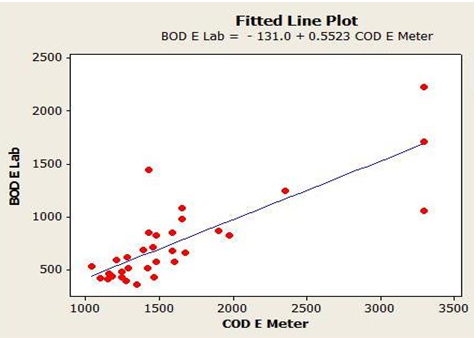

This technique has worked in multiple industries. TSS and turbidity have been used as predictor parameters for fats, oils & grease (FOG) and various metals (Figure 1), while COD has been used as a predictor parameter for biochemical oxygen demand (BOD) and other organics (Figure 2). COD has also been used to track product loss in food manufacturing facilities.