Stormwater & Wastewater Engineering

Helping facilities stay compliant, efficient, and in control of their water systems.

Whether you’re dealing with flooding, aging infrastructure, or evolving regulatory requirements, PSARA helps you understand your system, identify solutions, and implement upgrades that make sense.

We work with industrial clients, food manufacturers, petroleum retailers, and other regulated facilities to design and optimize stormwater and wastewater systems that are effective, maintainable, and built for real-world conditions.

Trusted by EHS Managers, Facility Engineers, and Plant Operators Across the Midwest.

What We Do

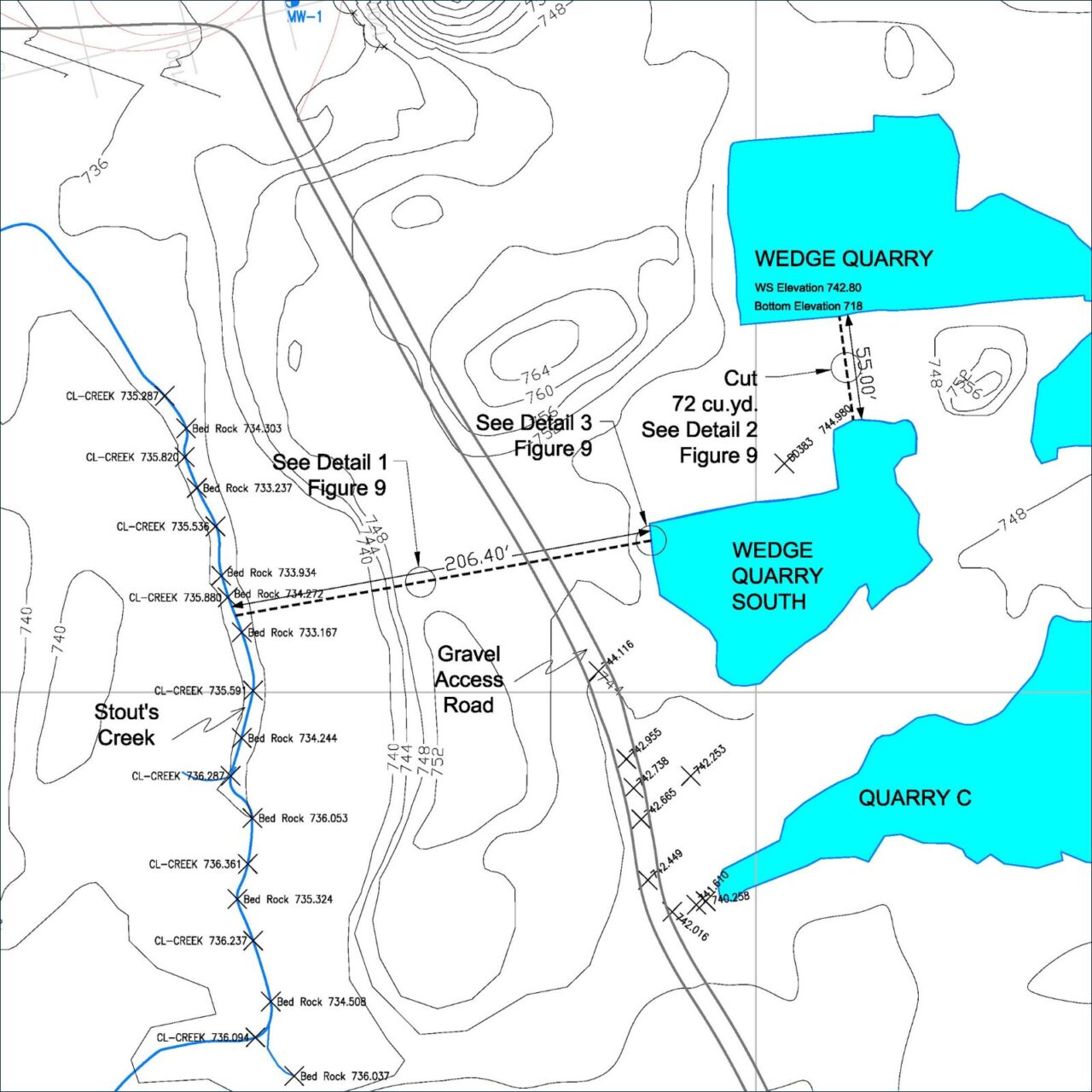

Stormwater Engineering & Infrastructure Design

We design and upgrade stormwater systems that manage flow, reduce flooding, and meet long-term site needs.

- Storm sewer and drainage design

- Detention/retention pond design and retrofits

- Flooding and runoff management

- Erosion and sediment control planning

- Design strategies to reduce pollutants like oil, grease, COD, and metals from stormwater runoff

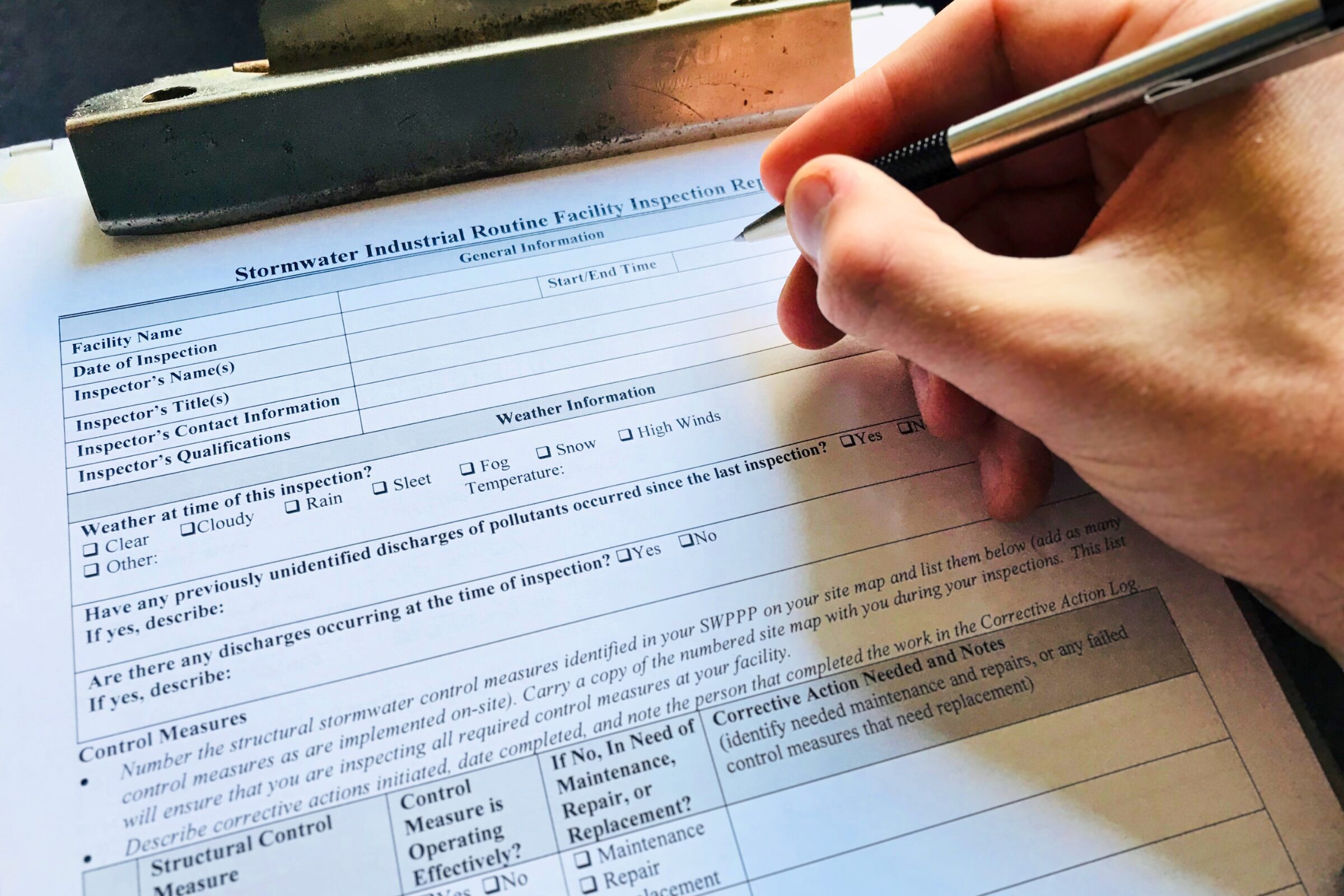

Stormwater Compliance & Permitting

We help facilities stay in compliance with evolving stormwater regulations through proactive planning and documentation.

- SWPPP development and implementation

- BMP planning and design

- Permitting support and regulator coordination

- Inspection readiness and documentation systems

Wastewater Pretreatment Design & Support

We design and upgrade pretreatment systems that meet discharge limits, reduce treatment costs, and simplify ongoing operations.

- Industrial pretreatment system design and retrofits

- Lift station and flow equalization design

- Nutrient and solids removal

- Equipment sizing and layout

- Permitting support and regulator coordination

Troubleshooting & Optimization

When systems aren’t performing as expected, we evaluate root causes and recommend targeted, cost-effective improvements.

- On-site system evaluations

- Sampling and performance assessments

- O&M support and SOP development

- Energy and chemical use reduction

Mobile Water Treatment Support

We support the setup and monitoring of temporary mobile treatment systems to address short-term or emergency discharge needs.

- Customized setups based on contaminants, flow, and site conditions

- Integration of bag filters, sand filters, carbon vessels, oil-water separators (OWS), and other modular components

- Onsite system assembly—often built directly in our trailer

- Rapid deployment for bypass, dewatering, and emergency response

- Real-time monitoring and compliance sampling

Why Clients Choose PSARA

We know what regulators are looking for.

Our team has a proven track record navigating regulatory programs and securing approvals that keep projects on schedule.

We design for long-term reliability.

Our systems prioritize functionality, maintainability, and cost-effectiveness over complexity.

We’re responsive and easy to work with.

You’ll get senior-level support, open communication, and a partner that follows through.